Hastelloy Clad Plate: An Engineering Solution for Extreme Corrosive Environments

In high-end industrial sectors such as chemical processing, aerospace, and energy, a material named Hastelloy Clad Plate is quietly becoming the "guardian" of equipment safety and longevity.

In today's industrial landscape, engineers and designers constantly face a ubiquitous threat—corrosion. It is not only a primary cause of equipment damage in chemical plants but can also trigger catastrophic accidents, endangering personnel safety and environmental health.

Simultaneously, budget constraints and cost control are realities that industries must contend with.

01. What is Hastelloy Clad Plate?

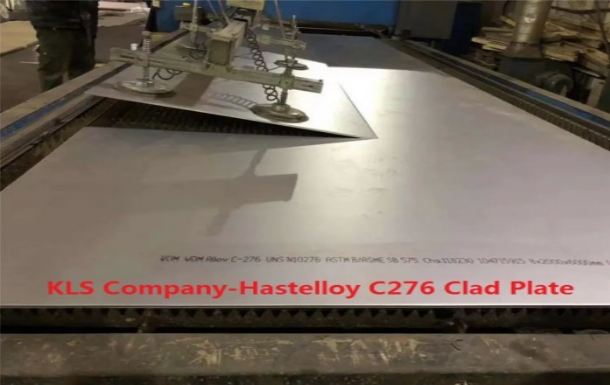

Hastelloy Clad Plate is a laminated material created by bonding high-performance Hastelloy with another metal (typically carbon steel or stainless steel) through specialized processes.

This structure grants it both the exceptional corrosion resistance of Hastelloy and the structural strength and cost-effectiveness of the base metal.

Hastelloy is essentially a nickel-based alloy, renowned for its outstanding corrosion resistance. It exhibits excellent resistance to most corrosive media in both oxidizing and reducing conditions, along with superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

The global Hastelloy market size is projected to reach a significant level by 2032, with the Chinese market also experiencing rapid growth, reflecting the material's increasing importance.

02. Technical and Performance Advantages

The core value of Hastelloy Clad Plate lies in its unique material combination approach. It adopts a "thin cladding on thick substrate" design philosophy, using expensive Hastelloy as the cladding layer. Only a small amount is needed to provide exceptional corrosion protection, while relying on the lower-cost base metal for primary structural support.

Hastelloy's ability to remain stable in extreme environments stems from its precise chemical composition design. Taking the Hastelloy C series as an example, they typically contain high proportions of elements like molybdenum and chromium, which form stable passive films that resist attack by various corrosive media.

For instance, Hastelloy C-276 is a nickel-chromium-molybdenum alloy containing tungsten, with very low levels of silicon and carbon, endowing it with superior overall corrosion resistance.

In terms of manufacturing processes, Hastelloy Clad Plates typically utilize hot roll bonding or explosive welding techniques to create a strong metallurgical bond between the different metals. This bond is so robust that the risk of delamination or separation in practical applications is minimized.

03. Application Fields and Scenarios

Hastelloy Clad Plate has demonstrated irreplaceable value across multiple industrial sectors.

In the chemical and petrochemical industry, it is used to manufacture components exposed to chlorinated organics and catalytic systems. Especially in environments handling chlorine-containing media, strong acids, and solvents, Hastelloy Clad Plate provides unparalleled protection.

Flue Gas Desulfurization (FGD) systems represent another critical application area. In these systems, Hastelloy Clad Plate is used for fabricating scrubbers, reheaters, wet gas fans, and other components, effectively resisting corrosion from acidic gases.

The pulp and paper industry also benefits from this material, where it performs excellently in digesters and bleach washers.

In recent years, with continuously increasing material performance requirements in the aerospace sector, the application of Hastelloy Clad Plate is also expanding.

For example, research teams at the Institute of Metal Research, Chinese Academy of Sciences, are exploring the application of additively manufactured Hastelloy X in related fields.

04. Selection and Processing Considerations

Selecting the appropriate Hastelloy Clad Plate requires comprehensive consideration of various factors. First, it is essential to define the corrosive environment the equipment will face, including parameters like medium type, concentration, temperature, and pressure.

Regarding structural design, different head forms (such as hemispherical, elliptical, dished, or conical) affect material usage efficiency and manufacturing costs. For instance, standard elliptical heads are often the preferred choice for balancing performance and cost, as their wall thickness matches the cylinder, simplifying procurement and welding processes.

Material selection is a crucial step. Determining the suitable cladding material based on medium corrosivity, temperature, and pressure is paramount—stainless steel-clad plates suit most chemical environments; titanium-clad steel plates resist chloride ion corrosion, widely used in seawater desalination, electrolyzers, etc.; while nickel-clad steel plates offer high-temperature oxidation resistance, ideal for catalytic cracking units.

During processing and manufacturing, special attention must be paid to the heat treatment conditions of Hastelloy Clad Plate. Workpieces must be kept clean before and during heat treatment, and contact with sulfur, phosphorus, lead, and other low-melting-point metals must be avoided, as these can degrade the alloy's properties.

Sulfur content in fuels must also be strictly controlled—less than 0.1% in natural gas and less than 0.5% in heavy oil.

05. Market Landscape and Supply Chain

The global Hastelloy market features a diverse competitive landscape, with major manufacturers including VDM Metals, High Performance Alloys, Haynes International, among others.

These companies have their own advantages in technological accumulation, product innovation, and market expansion, collectively driving industry progress.

Geographically, the production and consumption of Hastelloy are primarily concentrated in North America, Europe, and the Asia-Pacific region. As an emerging market, China has seen rapid demand growth in recent years, with local companies like Hubo Special Alloy (Shanghai) Co., Ltd., also continuously developing and growing.

It is worth noting that changes in the international trade environment in recent years, such as US tariff hikes, have impacted the export costs and supply chain layout of the Hastelloy C industry.

This has prompted some companies to reassess their supply chain strategies, considering diversified sourcing and production layouts.

The market prospects for Hastelloy Clad Plate are broad. It is predicted that the global Hastelloy market will maintain steady growth between 2025 and 2032, with strong demand particularly for segments like C276.

As industries like chemical processing, aerospace, and energy continue to demand higher equipment safety and longevity, Hastelloy Clad Plate is destined to find even wider application, providing a solid guarantee for human industrial civilization against the challenges of corrosion.