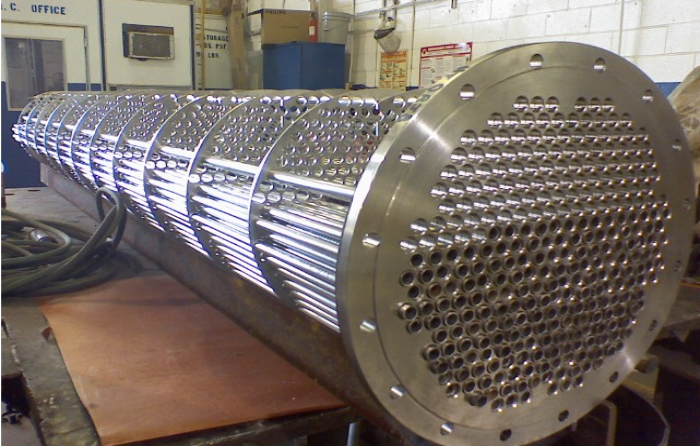

A round tube sheet in a heat exchanger or other similar equipment is a round circle plate with holes drilled in at optimal positions. The tube sheet holds the tubes in place within the heat exchanger to ensure effective heat transfer.

Overview

A round tube sheet in a heat exchanger or other similar equipment is a round circle plate with holes drilled in at optimal positions. Tubes then pass through these holes. The tube sheets hold the tubes in place within the heat exchanger to ensure effective heat transfer. In shell and tube heat exchangers, two clad plates support the tubes, one on each end.

Features

There are lots of benefits to using cladding materials to produce a tube sheet to achieve cost effectiveness, here at our company KLS, we have more than 10 years experience in the production of the cladded heat exchanger tube sheets in China.

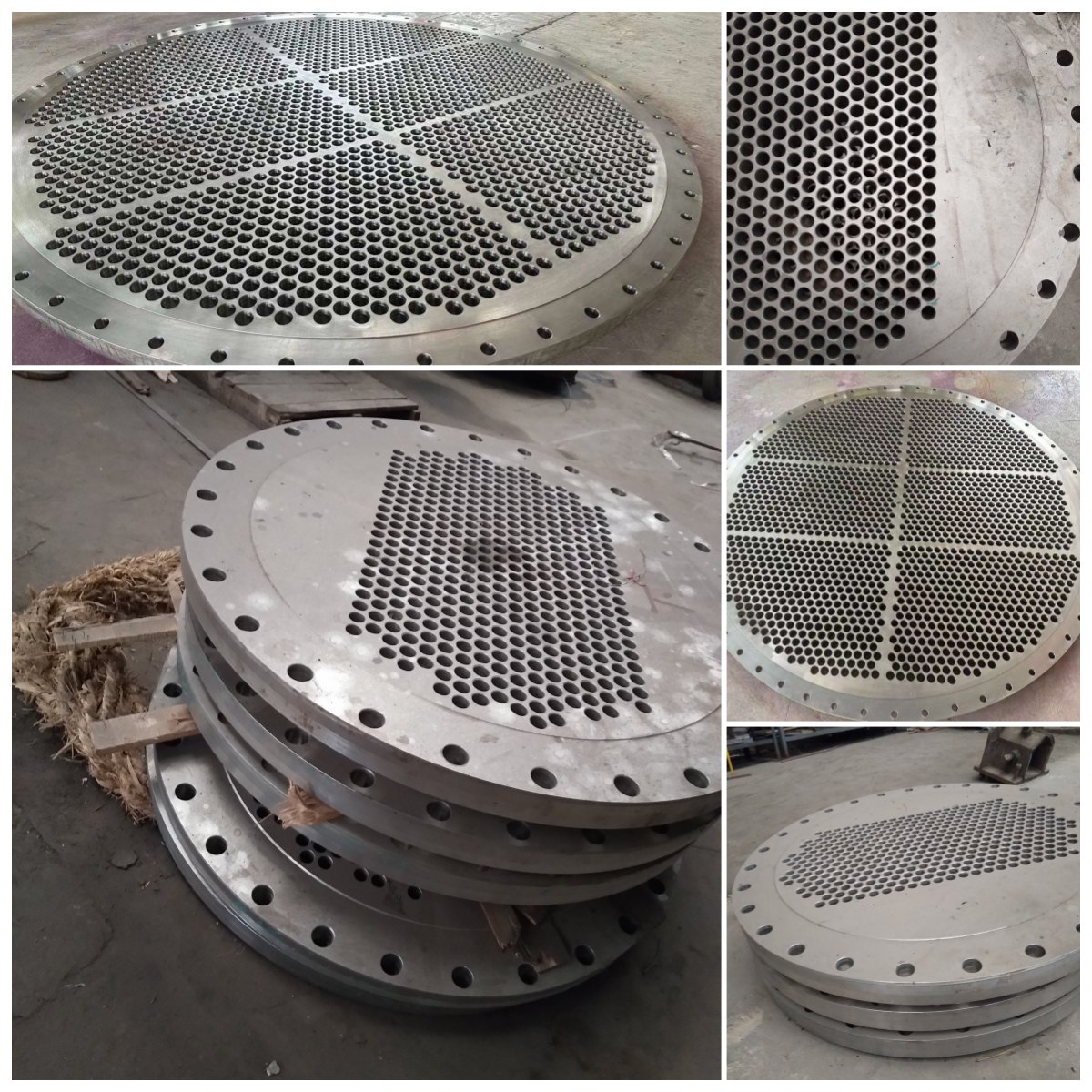

A tube sheet may be clad with a corrosion-resistant material that acts as both a protective barrier and thermal insulator. For cost efficiency, low carbon steel tube sheets are often overlaid with a thin layer of higher alloy metal. This bonded cladding provides enhanced corrosion resistance comparable to that of solid alloy materials, while significantly reducing material and manufacturing costs.

In a heat exchanger, numerous tubes are arranged within a sealed shell. Heat transfer occurs between the fluid flowing inside the tubes and the fluid circulating within the shell, each carrying different thermal energies. The tube sheet serves as a structural component that secures the tubes in place and maintains the integrity of the pressure boundary.

Tooling Concepts

◆ High-efficiency rough turning using a combination of high depth of cut (D.O.C) and high feed rate strategies

◆ Deep hole drilling solutions designed for exceptional productivity and precision

◆ Internal groove machining through milling, enabling process integration and reduced cycle time

◆ Cost-effective chamfering solutions offering high productivity and operational efficiency

◆ Base Material: Crafted from robust materials such as Carson steel plate, 16mn, and more, our tube sheets offer unwavering strength and longevity.

◆ Clad Material: Choose from a range of top-grade materials, including Titanium, C276, Monel, Stainless Steel, Zirconium, and more, ensuring corrosion resistance and durability.

◆ Production: Exchanger tube sheets are meticulously crafted using the explosion bonding technique, guaranteeing exceptional bonding and structural integrity.

◆ Customization: Tailored to your precise requirements, cald tube sheets come in a variety of dimensions, ensuring a perfect fit for your heat exchanger.

◆ Standards: Compliant with ASTM/ASME standards, tube sheet cladding meets the highest industry benchmarks for quality.

◆ Certifications: Rest assured with MTC, TPI, and ISO9001 certifications, signifying our unwavering commitment to quality control.

Specifications

| Item | Cladded heat exchanger tube sheet (explosion bonding) |

| Base Material | Carson steel plate, 16mn, ect |

| Clad Material | Titanium, C276, monel, stainless steel, Zirconium, etc. |

| Production | Explosion bonding |

| Dimension | Customized according to your needs |

| Standard | ASTM/ASME |

| Certificate | MTC, TPI, ISO9001 |

| Application | Petroleum, chemistry, electricity, paper making, alkali making, irrigation works, automobiles, salt, medicine, food and public facilities |

| Package | Standard export sea-worthy package |

| Delivery Time | Usually 15-25 days after receiving the 30% deposit |

| Payment terms | TT, L/C, DP or Negotiable |

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

| Note | We are so able to produce other standard as per the clients' requirements, Just let us know |

Uses

Heat exchanger tube sheets are used in a multitude of industries, including petroleum, chemistry, electricity, paper making, alkali making, irrigation works, automobiles, salt, medicine, food, and public facilities. Versatility is our strength.

Heat exchanger tubes, typically manufactured to TEMA (Tubular Exchanger Manufacturers Association) specifications, are available in a variety of materials, including low carbon steel, copper, admiralty brass, copper-nickel alloys, stainless steel, Hastelloy, Inconel, titanium, and others. Standard tube sizes generally range from 5/8 inch to 1-1/2 inch in outside diameter.

Tubes are commonly produced as seamless or welded. High-quality electric resistance welded (ERW) tubes offer a refined grain structure at the weld seam, contributing to enhanced mechanical integrity.

For specific applications, extruded tubes featuring low external fins and internal rifling are employed. These surface enhancements increase the metal’s effective area or induce turbulence within the fluid, significantly improving heat transfer performance. Finned tubes are especially advantageous when the shell-side fluid has a considerably lower heat transfer coefficient than the tube-side fluid. In such designs, the outer diameter in the finned section is slightly smaller than the landing area near the tube sheets, facilitating easy installation through baffles and supports while minimizing bypass flow.

U-tube designs are preferred in systems where large temperature differentials between fluids could cause thermal expansion issues in straight tubes. While U-tube bundles offer flexibility in accommodating expansion, they provide slightly less surface area due to the bend radius. Additionally, cleaning the curved ends is more challenging, and replacing inner tubes often requires removing outer layers or plugging the defective tube.

To address maintenance and serviceability concerns, U-tube configurations are typically used in conjunction with removable tube bundle designs, allowing for easier access and replacement when necessary.

Tube sheets are typically fabricated from round, flat metal plates with precisely drilled holes to accommodate tube ends in a defined pattern and spacing. The material of the tube sheet is usually selected to match or complement the tube material, considering mechanical and corrosion resistance properties. Tubes are secured to the tube sheet by methods such as pneumatic or hydraulic expansion, or mechanical rolling. To enhance joint strength, tube holes may be reamed or machined with one or more grooves.

In shell and tube heat exchangers, the tube sheet is exposed to both shell-side and tube-side fluids. Therefore, it must exhibit sufficient corrosion resistance and possess metallurgical and electrochemical compatibility with the operating fluids and flow velocities. For cost-effective corrosion protection, low-carbon steel tube sheets are often clad or overlaid with a thin layer of higher alloy metals, providing durability without the expense of full solid alloy construction.

The tube layout—defined by the hole pattern or "pitch"—determines the spacing and angular orientation of the tubes. By adjusting pitch design, engineers can control fluid velocity, pressure drop, and turbulence, optimizing surface contact and heat transfer efficiency.