When considering the purchase of clad metals, particularly clad plates, it is vital to be well-informed about the standards, certifications, and quality checks necessary to ensure optimal performance and durability. Clad plates, which typically consist of a base metal bonded with a layer of a different material, offer a unique combination of properties beneficial for various industrial applications. Understanding the relevant certifications and quality checks is essential for making an informed decision that aligns with project specifications and safety regulations.

Definition and Composition:

What are clad plates and their typical materials used (e.g., stainless steel, carbon steel)?

Applications:

Industries that commonly use clad plates, such as oil and gas, chemical processing, and construction.

Assurance of Quality:

How standards and certifications help in guaranteeing product quality and performance.

Compliance with Regulations:

The necessity for compliance with national and international regulations governing material safety and performance.

ASTM Standards:

Overview of relevant ASTM standards applicable to clad plates, such as ASTM B443 or ASTM A264.

ISO Certifications:

Importance of ISO 9001 for quality management systems in manufacturers of clad plates.

ISO 14001 for environmental management, relevant for sustainability concerns.

API Specifications:

API (American Petroleum Institute) standards specifically for industries utilizing clad plates.

Testing Processes:

Types of tests typically performed on clad plates, such as ultrasonic testing, radiographic inspection, and tensile testing.

Quality Assurance Protocols:

Important QA protocols manufacturers must adhere to in their production processes.

Research the Manufacturer:

How to research potential suppliers’ certifications and quality assurances.

Request Documentation:

Importance of asking for certificates and quality check reports before completing a purchase.

Ignoring Certifications:

Consequences of proceeding with purchases without verifying necessary standards.

Assuming One Size Fits All:

Understanding that different applications may require different certifications and quality checks.

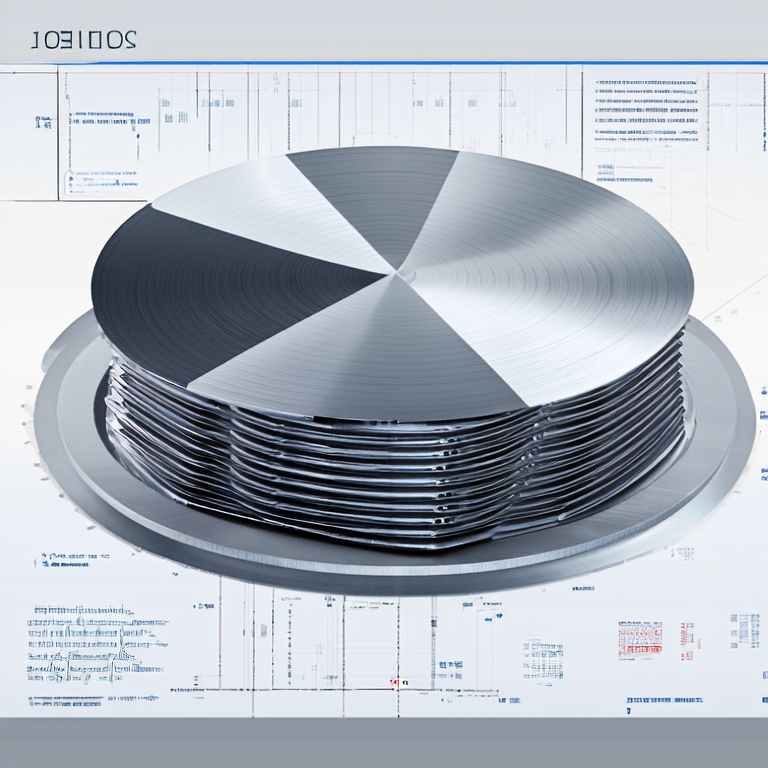

For better understanding, refer to the following image which showcases the clad process:

Future Trends in Clad Plate Quality Assurance:

Emergence of new technologies for testing and quality assurance.

Increased emphasis on sustainability and eco-friendliness in clad plate production.